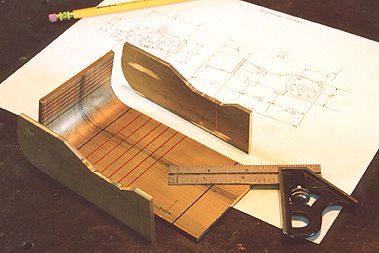

Dummy Stoker Engine

Here we have the start of the dummy stoker engine. Just some

1/8" brass so far.

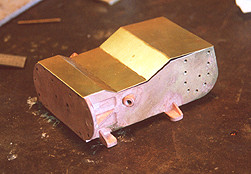

Dummy Stoker

Partially completed stoker engine, fitting the sheet metal lid.

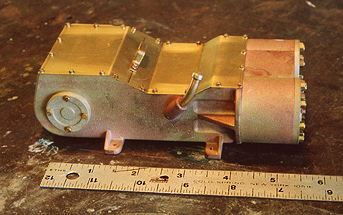

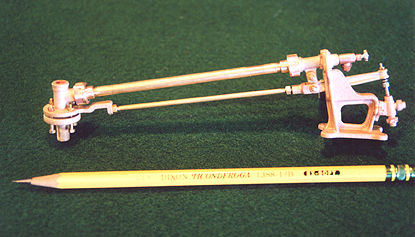

Stoker Engine

Here we have the completed stoker engine. Isn't it amazing what

you can do with some brass and a little silver solder. One thing

you can do when simulating a casting and you want some texture

is to go over your work piece with a dull center punch and then

sand blast it with some coarse sand. Even though this is just

a dummy stoker engine it actually serves a purpose on the Berkshire,

it hides the left-hand injector, as the full size engine had

no injector on this side. The injector is tucked up into the

stoker engine, and the delivery line comes out where the stoker

exhaust would be. On the full size Berkshire there is a large

exhaust line running from the stoker forward and disappears behind

the Worthington hot water pump, just perfect for an injector

delivery line.

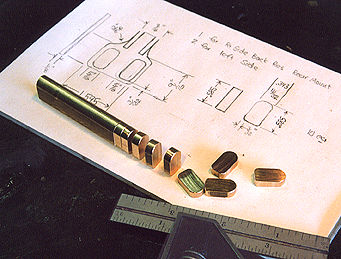

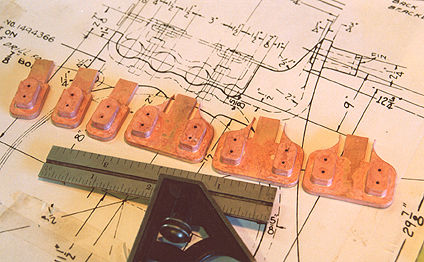

Running Board Supports

Modern steam had many examples of the pattern maker, and foundry

mans skill. One example on the Berkshires was the running board

supports. These were very complicated castings that had brackets

for the air tanks, assorted plumbing, and on one, there is a

platform for part of the original screw type power reverse. As

making patterns for these parts is beyond my abilities they were

fabricated from brass. There are six of them and they are all

different with many little bits to solder together. This photo

shows the mounting pads that fit against the boiler.

Running Board Supports

Boiler mounting pads.

Running Board Supports

Here we are silver soldering the upper mount to the main body

of the support. When soldering complicated assemblies like this,

flux everything and put it together with little screws that can

be filed off later. Always solder on a piece of fire brick, not

on a steel work table. A steel work table will wick all the heat

out of your work piece.

Running Board Supports

Completed support with plumbing clamps.

Running Board Supports

Here we have all six running board supports representing about

sixty hours of work. Large modern steam is festooned with little

bits of jewelry like this, and it just seems to go on and on.

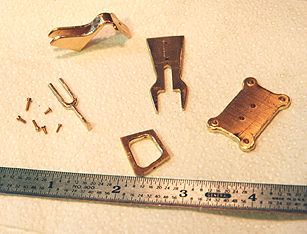

Low Water Alarm

Nickel plate Berkshires had a Nathan low water alarm mounted

on top of the boiler. Here we have the beginning's of one.

Low Water Alarm

Low water alarm pieces ready for assembly. The parts that represent

castings have been sand blasted with coarse sand.

Low Water Alarm

Completed low water alarm. It's

very interesting how these alarms worked. They mounted to the

top of the boiler with a pipe from the left end entering the

boiler vertically and extending down to minimum water level.

As long as water covered the bottom of this pipe, the upper horizontal

tube of the low water alarm would fill with condensate. If the

water in the boiler fell below the bottom of the vertical pipe,

the condensate would drain from the alarm allowing the horizontal

tube to fill with steam. When this happened it caused the horizontal

tube to heat up and expand. As the metal rod under the tube didn't

expand, it caused the lever connecting them to push down the

plunger at the lower right, opening a valve that blew a whistle

in the cab. A friend of mine who has a lot of experience with

full size stationary boilers said they had exactly the same alarm,

but that instead of blowing a whistle, it turned on the feed

water pump.

{BACK}

copyright

© 2004-2006, Jack Bodenmann, all rights reserved.